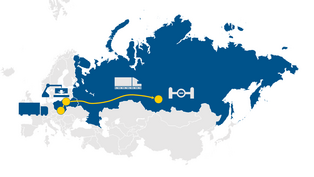

Delivery of heavy equipment for SUEK

Client

SUEK is one of the five largest coal suppliers to the world coal market. The Kuznetsk coal basin, or Kuzbass, located in Kemerovo Oblast, is one of the largest coal deposits in the world. SUEK produces high-quality hard coal at three open-pit and seven underground mines in Kuzbass. SUEK also generously invests in mechanization and automation of works to accelerate production rates and ensure labor safety.

SUEK’s Objectives

To deliver coal mining equipment (shield supports*) from Poland to Kuzbass and carry out import customs clearance with centralized coordination at each stage of transportation.

*Shield support — a self-propelled temporary artificial structure preventing the collapse of rock in mines. Since the weight of one shield support is about 30 tons, this equipment is classified as outsized cargo. This means that they are difficult to accommodate in standard vehicles, and transportation of such goods is associated with increased risk and therefore requires compliance with special rules. GEFCO Russia has extensive experience in handling outsized cargo.

GEFCO Russia's Solution

Since 2014, 5 transportation projects have been implemented. The logistic arrangements were analyzed and optimized after each project. In the first project, the cargo was transported by truck, and then transferred and taken through customs clearance in Smolensk. This method of delivery revealed certain problems, so GEFCO Russia’s Logistics Solutions Department developed a new logistics arrangement — direct rail transportation on universal rail platforms from the manufacturer’s plant in Poland to Kemerovo Oblast. Due to the difference in railroad gauge in Europe and the CIS, cargo has to be transferred from Polish to Russian platforms at the Polish-Belarusian border. However, this inconvenience is compensated by the fact that rail transport is much more reliable than road transport both in terms of time and technology for outsized cargo transportation.

The solution developed in this project for import customs clearance is of particular interest. After the transition from road transport to direct delivery by rail, clearance of cargo upon arrival in Kemerovo Oblast became the most profitable option. However, this method requires closing a section of railroad track to create a temporary customs control zone for inspection of equipment and vehicles. This is not an easy task in the country’s main coal region, but working with Russian Railways meant the project team was able to implement the plan.

Result

The first deliveries of equipment were made in 2015. In just a few years, several hundred pieces of equipment have been delivered to various cities in Kemerovo Oblast. All cargoes were shipped within the agreed time frame and without incident.

GEFCO Russia’s project team provided a comprehensive door-to-door service that included:

- transportation from the warehouse of origin to the destination warehouse

- cargo handling at stations

- transferring shipments during the transition from European to Russian railroad gauge

- import customs clearance

- cargo insurance

Working in Control Tower mode (control and dispatching at each stage of transportation as a “one-stop-shop”) made it possible to minimize the cost of coordination of project participants.

Cost and risk analysis was carried out at each stage of delivery, which made it possible to develop an optimal transportation scheme providing maximum reliability in terms of delivery time and outsized cargo transportation technology.

More solutions by GEFCO Russia

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/8/d/csm_tjazhelye-i-negabaritnye-gruzy_c44fab11c7.jpg)

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/b/e/csm_zheleznodorozhnye-perevozki_294ef0afb2.jpg)